How is Maple Syrup Made?

Nature's gift

Known for its deliciously sweet taste and strong ties to Canada, maple syrup has been adopted by foodies from all around the world.

While most of us are aware maple syrup is a natural product, the exact process that yields the delicious syrup remains a mystery for many people.

So, where does maple syrup come from? How is maple syrup made? And in what ways has maple syrup farming changed over the years? Let’s find out!

Where does maple syrup come from?

More than 70% of the world’s maple syrup comes from Quebec, comfortably making the Canadian province the global leader in maple syrup production. In Quebec, maple syrup represents one of the biggest industries, supporting over 13,300 producers working across more than 7,000 farms.

As you might expect, maple syrup comes from maple trees. More specifically, it is derived from the sugary sap that’s extracted from these trees in early spring.

There are more than 150 species of maple trees found around the world, and while all of these can theoretically be used to make maple syrup, only a few are abundant enough to be used in practice.

Sugar maples make up most of the trees used by maple farmers in Quebec, with red maples also common. Silver and black maples are used too, but to a much lesser extent.

The sap found in these species contain high concentrations of sugar (1.5–3.5%), meaning more maple syrup can be produced from a smaller quantity of sap.

So, if you wanted to definitively answer the question, “where does maple syrup come from?”, your best bet would be a sugar maple tree from Quebec!

Learn more about the different species of maple tree below.

How is maple syrup made?

Maple syrup is made by boiling the sap found in maple trees at a set temperature to reduce its water content. During this process, the sap thickens to the consistency of a syrup and its sugar levels increase until the distinctive flavour so many of us recognise as maple is reached.

But let’s not get ahead of ourselves – a series of climatic events must first take place before the sap can be extracted from the trees.

The process begins in summer, when higher levels of photosynthesis produce a surplus of sugar. As the colder temperatures of autumn and winter take hold, these nutrients are stored as starch in the roots.

When spring rolls around, the alternating freeze-thaw cycles of day and night helps the sap that has been stored away during winter move freely around the tree.

The relative heat of daytime liquifies the sap, causing the gas in the tree’s fibres to expand and creating pressure that pushes the sap out towards the trunk and branches.

Pure maple syrup is a natural product derived entirely from the sugary sap found in maple trees.

From here, the liquid can be safely extracted without damaging the tree. Small holes are drilled into the trees and tubes are then inserted to ‘tap’ the sap.

The tubes carry the maple sap to the nearest sugar shack, where it is transferred to a large steel tank ready for processing in an evaporator.

Boiling the maple sap removes the excess water, eventually forming a rich and sweet-tasting syrup. Once the sap reaches a sugar content of 66%, it has officially become maple syrup!

The production process for Canadian maple syrup is unique in that it only requires a single ingredient – maple tree sap – and is entirely free of additives.

This is not the case for ‘maple-flavoured’ blends, which are heavily processed and typically mixed with refined sugars like inverted sugar syrup.

See the entire production process for yourself above.

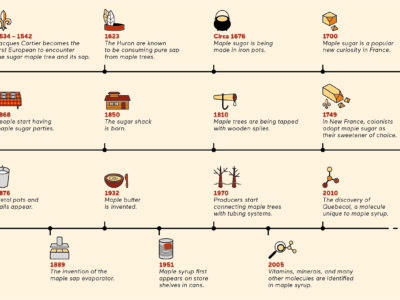

How has maple syrup farming evolved?

The maple syrup industry has come a long way since the earliest references to maple tree tapping from the 17th and 18th centuries.

Native Americans and early European settlers in Canada were known to use axes to make incisions in maple trees and place buckets underneath to collect the sap.

Rather than being taken to a sugar shack, the sap would simply be heated in an iron pot over an open fire at the nearest settlement.

Before long, however, the rising demand for maple syrup called for more advanced methods capable of increasing production.

The 19th century brought about several game-changing innovations, including wooden spiles for tapping the trees and metal pots for collecting the sap, as well as the iconic sugar shack.

By the late 1800s, the first evaporators were being rolled out across Canada’s maple farms, enabling exponentially larger amounts of maple syrup to be produced.

Production capacity has since developed further, notably through the implementation of vast tubing networks that carry the sap directly to the sugar shack either by gravity or vacuum.

Many maple farms are now also using reverse osmosis units, which can help separate the water from the sap before it is boiled in an evaporator.

These technologies are helping to make the production process more efficient, not only in terms of output but also by reducing energy consumption.

So while climate change is making crop yields increasingly unpredictable, the maple syrup industry’s resilience and adaptability are helping to offset climate-related losses.

Learn more about the impact of climate change on maple syrup farming below.

Maple syrup: nature’s gift

Made solely from the sap found in maple trees, maple is a one-of-a-kind product that serves as a fantastic natural alternative to refined sugars. Just make sure to look for the words ‘pure’ or ‘organic’ on the bottle so you know it’s 100% maple!

Has all this talk of maple syrup whet your appetite? Check out our range of recipes with maple syrup for hundreds of delicious meal ideas, each enriched with the natural sweetness of pure maple syrup.

Hundreds of Delicious Recipes

Maple is a special addition to any recipe, from starters and snacks to sumptuous desserts. Find one that’s perfect for you, your family and friends.

)